Views: 8 Author: Site Editor Publish Time: 2022-06-17 Origin: Site

With the continuous advancement of social technology, there are many types of terminals on the market. Terminals are a necessary product for electrical equipment and decoration. Terminal boxes belong to the connector industry and are used to facilitate the connection of wires. With the increasing degree of industrial automation and the stricter and more precise requirements of industrial control, the amount of terminal blocks is gradually increasing. There are many types of terminal blocks to choose from, so what are the most common ones? What do each of them look like? The following Xiaobian Linkwell will take you to understand.

The most common terminal blocks are divided into the following categories:

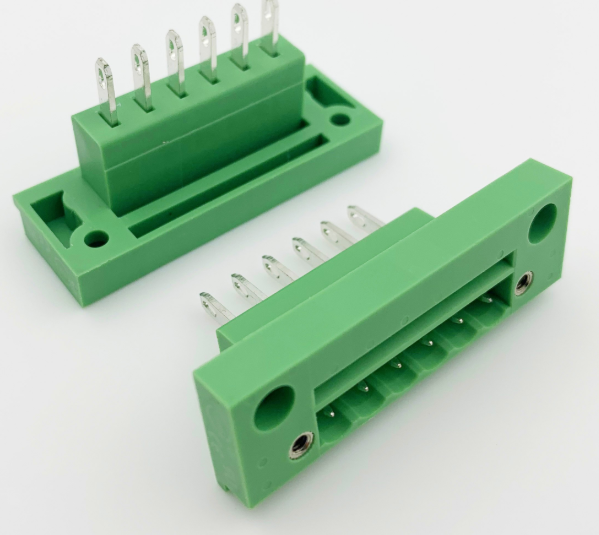

1. In-line terminal

Generally, it is made of two parts plug-in connection, one part presses the wire, and then plugs into the other part, which is soldered to the PCB board. This is the mechanical principle of the bottom, and this anti-vibration design ensures the long-term airtight connection of the product and the reliability of the finished product.

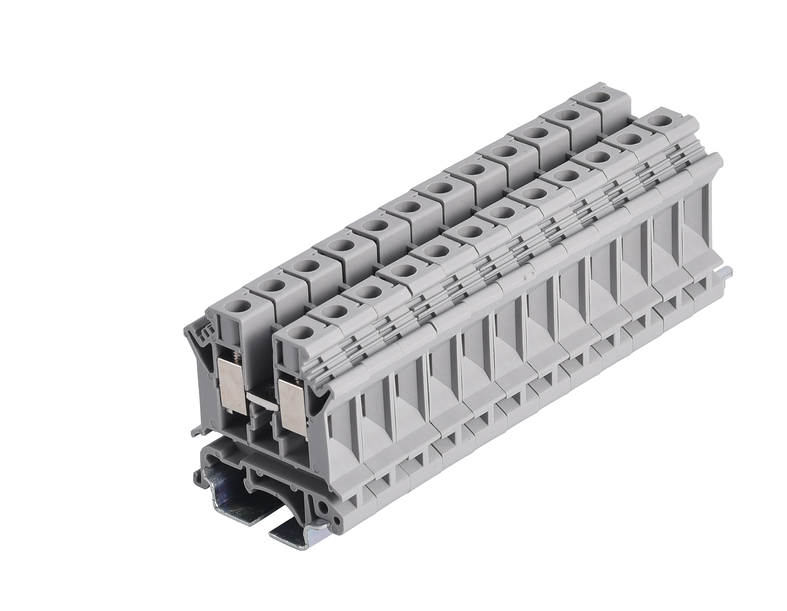

2. Spring terminal

Spring-type terminals are new types of spring-type terminals, which have been widely used in the world's electrical and electronic engineering industries: lighting, elevator lift control, instrumentation, power, chemistry, and automotive power.

When spring-type PCB terminals are usually connected, attention should be paid to the selection of voltage and current. Too high voltage and current will damage the circuit board, so we need to choose suitable bearing products when selecting PCB terminals.

3. Wall terminal

The through-wall terminals can be installed side by side on panels with thicknesses ranging from 1mm to 10mm, and can automatically compensate and adjust the thickness of the panel to form a terminal block with any number of poles. In addition, isolation plates can be used to increase air gaps and creepage distances.

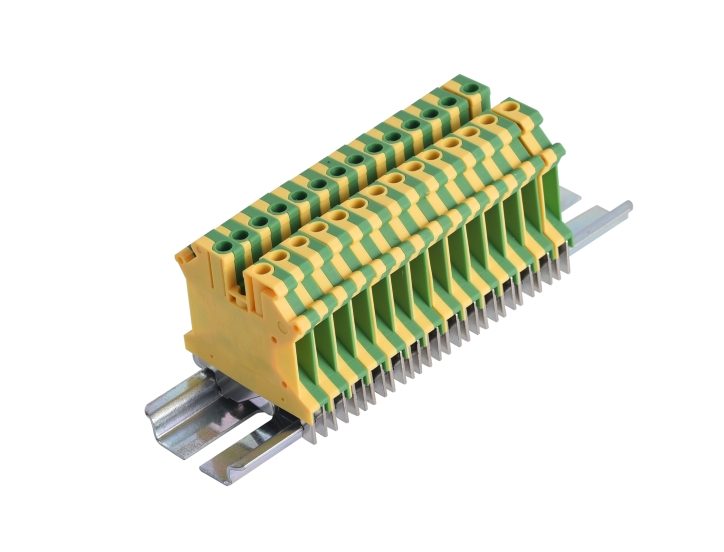

4. Rail terminal block

Rail-type terminal - the screw is made of high-strength copper alloy, the conductor is made of electrolytic copper, and the crimping frame is made of alloy copper that is resistant to stress crack corrosion. The unique crimping structure has good self-locking and anti-loosening performance. These metal surfaces are also protected by tin or nickel plating. All-copper terminal blocks avoid the battery effect of steel metal parts and copper conductors in wet environments.

5. Barrier terminal

Barrier Terminal Blocks are designed for electrical applications and incorporate a flip-top clear safety cover. Barriers allow for messy or frayed wire ends to prevent electrical shorts between locations on the same terminal block and adjacent components.

The above is an introduction to some common terminal types. I hope it can help you answer your doubts. There are many types of terminal blocks. You can choose according to your actual needs. You are welcome to leave a comment~~~

Shanghai Linkwell brand specializes in the production of famous terminal blocks, and is an integrated manufacturer of production and sales. The products sell well in more than 80 countries. The company has passed CE certification and other certificates, and is widely used in new energy, photovoltaic, automation, high-tech main industries and electricity. In the fields of control machinery and equipment, the company has achieved a leap from traditional manual methods to workflow and automation. Welcome to inquire: 400-671-6715

Copyright ©️ LINKWELL ELECTRIC (Shanghai) Co., Ltd. 沪ICP备12048522号-2

cooling fan

Axial Fan

top exhaust fan

Centrifugal fan

DC fan

Industrial air conditioner

transformer

Terminals

thermostat

heater

Distribution Cabinet

waterproof box

Electric control cabinet accessories