Views: 12 Author: Site Editor Publish Time: 2025-11-20 Origin: Site

In modern electrical systems, terminal blocks serve as the central hub for circuit connections, providing a safe, organized, and efficient solution for connecting wires and cables. Whether you work in industrial automation, power distribution, control panels, or HVAC systems, proper use of terminal blocks is crucial for ensuring long-term stable operation of electrical systems. This article offers comprehensive insights into usage methods, best practices, and selection criteria for high-quality terminal block products.

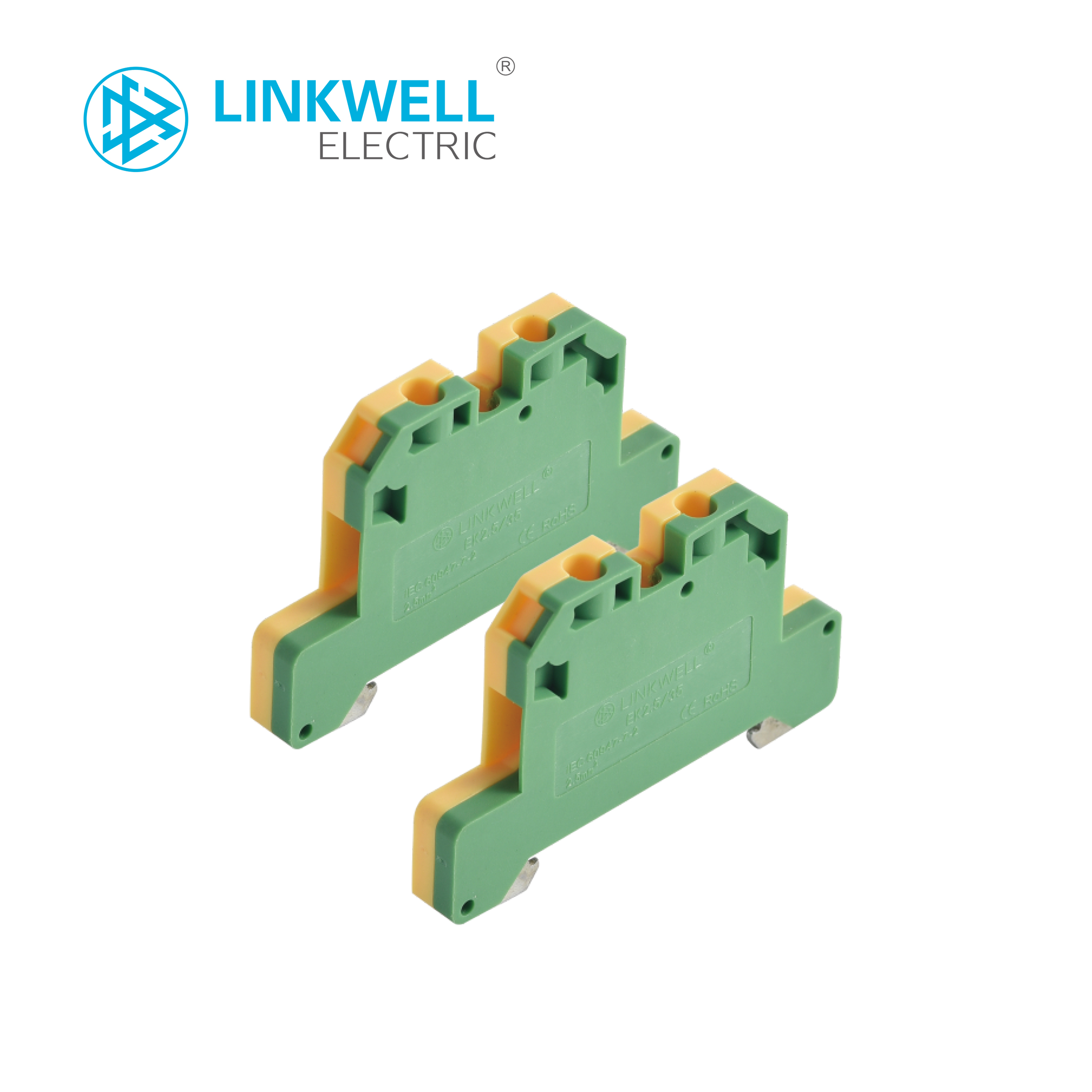

What is a Terminal Block?

A terminal block is a device used for electrical connections, providing a reliable and systematic method for connecting multiple wires and cables. As the central hub of an electrical system, it simplifies the wiring process and enhances system maintainability and safety. By using terminal blocks, technicians can easily organize circuits, reduce wiring errors, and ensure every connection is secure and reliable.

Application Areas of Terminal Blocks

Terminal blocks play a vital role in various electrical environments:

Industrial Automation: Provides stable signal and power transmission in automated production lines and machine control.

Power Distribution: Safely distributes power to various branch circuits within distribution systems.

Control Panels: Organizes complex wiring inside control cabinets, improving maintainability.

HVAC Systems: Connects various electrical components within heating, ventilation, and air conditioning systems.

Preparation: Tools and Safety Measures

Essential Tool List

Before starting work with terminal blocks, preparing the appropriate tools is crucial:

Wire Strippers: For precisely removing insulation from wire ends without damaging the conductor.

Screwdrivers: Select the correct type and size for the terminal screws to fasten or loosen connections.

Linkwell Terminal Block Connectors: The core component of your electrical project.

Multimeter: For checking connection quality, testing voltage, and verifying continuity.

Labels or Markers: Help identify and track each wire.

Safety Gloves and Goggles: Protect against accidental injury during work.

Safety Precautions

Safety is always the primary concern in electrical work:

Disconnect Power: Always disconnect power before touching any wires or terminal blocks.

Verify Power is Off: Use a multimeter to confirm the absence of voltage in the circuit.

Select the Appropriate Terminal Block: Ensure the terminal block meets your voltage and current requirements.

Secure Installation: Mount the terminal block securely and tighten all connections according to the manufacturer's recommendations.

Proper Labeling: Clearly mark voltage and current information on each terminal block.

Follow Standards: Adhere to international standards such as the National Electrical Code (NEC) and International Electrotechnical Commission (IEC) standards.

How to Use Terminal Block Connectors: A Detailed Step-by-Step Guide

Step 1: Prepare the Wires

First, gather all wires needed for the project, ensuring they can reach the terminal block without excessive stretching:

Cut each wire to a suitable length, leaving enough slack for future maintenance.

Refer to the manufacturer's instructions for wire length requirements for specific types of terminal block connectors.

Double-check all wire lengths to ensure a neat and orderly setup.

Step 2: Strip the Insulation

Use wire strippers to precisely remove the insulation from the wire ends:

Make a clean cut, avoiding damage to the conductor.

The strip length should match the terminal block's design, ensuring the conductor is fully inserted into the clamping mechanism.

Avoid stripping too much or too little – just enough for a tight connection.

Step 3: Identify Terminal Positions

Examine the terminal block and find the correct position for each wire:

Most terminal connectors have clear markings or color coding.

The modular design of Linkwell terminal blocks makes organizing connections easier.

Match each wire to its correct position, especially when connecting power sources or handling multiple circuits.

Label each wire and terminal position for future tracking and troubleshooting.

Step 4: Insert and Secure the Wires

Insert the wires into their designated slots on the terminal block:

Ensure the correct wire gauge is used to prevent loose connections.

Securely mount the terminal block to prevent movement.

Tighten the clamping screws to firmly secure the wires in place.

Linkwell's secure clamping design helps prevent loose connections and ensures long-term reliability.

Step 5: Check Connections

After completing all connections, carefully inspect your work:

Visual Inspection: Confirm all wires are fully inserted and screws are properly tightened.

Tug Test: Gently pull on each wire to ensure they are firmly fixed.

Electrical Continuity Test: Use a multimeter to check continuity and ensure reliable connections.

Temperature Check: Check terminal temperature after operation; it should not be overheating.

Step 6: Test the Setup

Use a multimeter to test the connections and ensure everything is functioning correctly:

Set the multimeter to resistance or continuity test mode.

Before testing, ensure the connector is disconnected from all power sources.

Connect the test leads to the terminals and check that resistance is less than 1 ohm.

Record the resistance value for each connection to help identify trends and potential issues early.

Troubleshooting and Professional Tips

Ensuring Correct Terminal Connections

Achieving reliable terminal connections requires attention to multiple details:

Cable Entry Direction: Choose the right direction for your setup – horizontal, vertical, or 45°.

Cable Fixing Method: Select screw, push-button, or push-in types based on needs.

Safety Ratings: Ensure terminal blocks comply with UL, IEC, and other safety standards.

Current and Voltage Ratings: Always stay within rated limits to prevent overheating or damage.

Safety Features: Look for insulation materials and barriers to prevent accidental contact and short circuits.

Avoiding Common Mistakes

Even experienced electrical engineers can make mistakes with terminal blocks:

Using incorrect tools for stripping or tightening.

Over-tightening or under-tightening screws.

Incorrect wire alignment within the terminal.

Neglecting waterproofing for outdoor installations.

Skipping the final inspection step.

Using damaged connectors or wires.

Rushing the installation process.

Selecting connector types unsuitable for the specific environment.

Problem Resolution Guide

If a terminal block malfunctions, most issues can be resolved by following these steps:

Check all screws and fasteners, tightening them to the recommended torque.

Perform a visual inspection and gently tug each wire to confirm it is secure.

Look for signs of overheating or discoloration.

Use a torque-limiting screwdriver to avoid over-tightening.

Regularly inspect terminal strips, especially in high-vibration areas.

Why Choose Linkwell Terminal Blocks?

Excellent Product Features

Linkwell terminal blocks don't just provide connectivity; they are designed for performance and safety:

Multiple Connection Methods: Offers various configurations, ensuring the right solution for every project.

Stringent Quality Standards: Delivers reliable performance even in harsh environments.

Robust Materials: Housings use materials like polyamide and nylon with high insulation, heat resistance, and flame retardancy.

High-Quality Conductors: Current conductors use brass or copper for excellent conductivity, often tin-plated for corrosion resistance.

Reliable Clamping Screws: Made from galvanized steel, ensuring stable and reliable connections.

Comprehensive Certifications: All terminal blocks comply with important certifications like UL, CE, and IEC.

Wide Industrial Applications

Linkwell terminal blocks excel in various environments demanding high reliability:

Three-Phase Power Distribution: Manages high power loads in factories and commercial buildings, connecting outlets over large areas.

Control Panel Wiring: Simplifies control panel wiring, keeping wires organized and reducing accident risks.

Harsh Environment Adaptation: Provides durable and safe performance in high humidity, extreme temperatures, or chemically exposed environments.

International Standard Compliance: UL and IEC certifications demonstrate these terminal blocks can handle demanding industrial conditions.

Summary

Correctly using terminal block connectors is crucial for ensuring the safe and reliable operation of electrical systems. Here is a brief recap of the key steps:

Select the appropriate terminal block for the project.

Strip wires precisely and connect them securely.

Label each connection clearly.

Regularly check the setup's condition.

Keep all components clean and organized.

According to statistics, nearly 30% of electrical failures stem from connection issues, making careful work essential for safety. Choosing a trusted brand like Linkwell helps you avoid the following risks:

Overheating or short circuits caused by loose connections.

Unstable signals and power outages due to poor contact.

Additional time and costs resulting from maintenance challenges.

For complex or high-voltage applications, consulting a professional electrical engineer is recommended.

Frequently Asked Questions

How to choose the right terminal block connector for your project?

First, assess voltage and current requirements, and check wire size and number of connections. Linkwell offers multiple options, ensuring you can always find a solution suited to your specific equipment.

Can terminal block connectors be reused?

Yes, most terminal block connectors can be reused if in good condition. However, always check for damage or wear before reuse. Replace any connector that appears cracked or worn.

What should I do if the wire keeps slipping out?

Ensure the wire is stripped to the correct length, fully inserted into the terminal, and the screw is tightened appropriately (not over-tightened). If the problem persists, check the connector for damage.

Are Linkwell terminal block connectors suitable for outdoor use?

Linkwell offers terminal blocks with robust insulation and weather-resistant materials. For outdoor projects, select models specifically designed to resist moisture and temperature variations, and always follow the product guidelines for best results.

By following the recommendations and best practices in this guide, you can ensure safe and reliable electrical connections, providing long-term stable performance for various applications. With their exceptional quality and reliability, Linkwell terminal blocks are the ideal choice for industrial, commercial, and residential electrical projects.

Copyright ©️ LINKWELL ELECTRIC (Shanghai) Co., Ltd. 沪ICP备12048522号-2

cooling fan

Axial Fan

top exhaust fan

Centrifugal fan

DC fan

Industrial air conditioner

transformer

Terminals

thermostat

heater

Distribution Cabinet

waterproof box

Electric control cabinet accessories