Views: 34 Author: Site Editor Publish Time: 2025-10-23 Origin: Site

In the field of electrical engineering, the PTC (Positive Temperature Coefficient Thermistor) is a small yet powerful electronic component that plays a crucial role in circuit protection. This unique component has the characteristic of increasing its resistance as temperature rises, making it an ideal choice for safety protection and automatic regulation in electrical systems. PTC technology is in wide demand across global industries. As market demand continues to grow, PTC's important position in modern electrical infrastructure becomes even more evident.

PTC Key Takeaways at a Glance

Self-Protection Mechanism: PTC thermistors automatically increase resistance as temperature rises, acting like a safety switch to protect circuits from overheating damage.

Cross-Industry Application: Multiple industries, from automotive to medical devices, rely on PTCs for reliable overcurrent protection.

Material Differences: Ceramic PTC thermistors offer rapid response and high stability, while polymer PTCs are more cost-effective in simpler applications.

Maintenance Convenience: PTCs can reset automatically after overloads, unlike traditional fuses that require replacement, effectively reducing maintenance costs.

Energy Efficiency Performance: Using PTC heaters in industrial environments improves energy utilization and protects sensitive electronic equipment from temperature fluctuations.

Understanding PTC In-Depth

PTC Basic Concepts

PTC is the abbreviation for "Positive Temperature Coefficient Thermistor." This component can be found in various devices, from industrial machinery to everyday electronics. The most notable feature of a PTC is that it changes its resistance value with temperature. This unique performance makes it the preferred solution for circuit protection and temperature regulation.

The term "Positive Temperature Coefficient" accurately describes the material property – resistance increases with rising temperature. You can think of a PTC as a built-in safety switch: when equipment overheats, the PTC automatically intervenes and limits current, providing protection for the device.

PTC Material Composition

Common PTC materials include:

Ceramic PTC: Uses doped barium titanate (composed of barium carbonate and titanium dioxide), which is highly sensitive to temperature changes, making it very suitable for circuit protection.

Polymer PTC: Contains conductive particles such as carbon within a polymer matrix, providing a cost-effective alternative.

Barium Titanate (BaTiO₃): As the core material for ceramic PTCs, it is known for its reliable temperature-resistance characteristics.

PTC Industry Applications

PTC thermistors are widely used in various industries:

| Application Field | Specific Uses |

|---|---|

| Manufacturing | Overcurrent protection in automated equipment |

| Automotive Industry | Preventing electrical faults in hybrid and electric vehicles |

| Consumer Electronics | Enhancing safety and reliability of complex devices |

| Medical Devices | Ensuring safe and stable operation of critical medical equipment |

Detailed Explanation of Positive Temperature Coefficient Working Principle

The PTC effect is key to understanding its working principle. When temperature increases, the resistance of the PTC material increases, but this is not a simple linear change. At low temperatures, the PTC resistance remains low and stable; in the initial stage of temperature rise, resistance may slightly decrease; once a specific temperature point (the Curie temperature) is reached, the resistance rises sharply. This sudden change acts like a fuse, effectively stopping current flow and protecting the system.

From inside the material, rising temperature causes increased lattice vibrations. These vibrations scatter electrons, making them more difficult to move, thus increasing resistance. When the temperature reaches the Curie point, the material undergoes a phase transition, causing a sharp increase in resistivity, much like switching a toggle.

The impedance-temperature curve of a typical PTC thermistor shows:

Initial stage with a small decrease in resistance (NTC region)

After the switching point, resistance rises sharply within a narrow temperature range

After the Curie point, the curve is almost vertical, showing the PTC's rapid response capability

The Positive Temperature Coefficient effect provides crucial safety guarantees for the system, giving the PTC self-regulating capability. When equipment overheats, the PTC automatically increases resistance and cuts off the current, achieving protection without the need for additional fuses or switches.

Practical Advice: When designing systems requiring automatic overheat protection, PTC thermistors are a wise choice, especially in critical applications, as they provide reliable performance assurance.

PTC Working Mechanism

Self-Regulating Principle

Using a PTC thermistor in a circuit is equivalent to having a built-in safety feature. This device knows how to protect itself and your equipment. The self-regulating principle is as follows:

When current is too high, the PTC thermistor automatically limits the current.

When current exceeds safe levels, the thermistor's resistance increases rapidly, protecting the circuit from damage and preventing overheating.

PTC heating elements undergo a drastic change in resistance at a specific temperature point: below this point, they allow current to pass and generate heat; above this point, they almost block current, maintaining a stable temperature.

Even if voltage or thermal load changes, the PTC can maintain temperature stability, with no need to worry about surges or sags.

Technical Tip: Consider the PTC thermistor as an intelligent protector for electronic equipment. When the temperature is too high, it automatically intervenes to ensure safe operation.

The Importance of Curie Temperature

The Curie temperature is a key parameter for PTC thermistor operation. When the temperature is below this point, the resistance remains low and stable. As the temperature approaches the Curie temperature, special changes occur inside the thermistor: the ceramic material changes its crystal structure, making it difficult for charges to move, and resistance increases rapidly.

This sudden increase in resistance is the source of the PTC's self-regulating ability. When the temperature exceeds the Curie point, the thermistor almost blocks the current, effectively preventing overheating and ensuring equipment safety. The Curie temperature marks the turning point for the PTC from conducting to blocking current, making it very suitable for overcurrent protection and temperature sensing.

Types of PTC Thermistors

PTC thermistors mainly come in two types: Ceramic and Polymer. Each has unique advantages and is suitable for different application scenarios.

Ceramic PTC Thermistors

Ceramic PTC thermistors use a special doped barium titanate material and are often used in occasions requiring fast and reliable protection. Ceramic PTCs exhibit a sharp increase in resistance at a specific temperature point, effectively protecting equipment from overheating or power surges.

Main characteristics and typical applications:

| Key Characteristics | Typical Applications |

|---|---|

| Special R-T Curve | Temperature Monitoring |

| Defined Switching Temp (Tₛ) | Thermal Protection |

| Doped BaTiO₃ Material | Overcurrent Protection |

| Sharp R increase at Tₛ | Consumer Electronics & Automotive |

Ceramic PTC thermistors are widely used in automotive, household appliances, and industrial equipment, performing excellently in temperature monitoring and overcurrent protection. If fast response and stable performance are required, the ceramic type is the ideal choice.

Note: Ceramic PTC thermistors usually feature a multilayer design with small package sizes, facilitating installation in compact spaces.

Polymer PTC Thermistors

Polymer PTC thermistors mix conductive particles within a polymer matrix, making them very suitable for simple overcurrent and temperature detection tasks. If an economical, practical, and easy-to-use solution is needed, Polymer PTCs are a wise choice.

Polymer vs. Ceramic PTC Comparison:

| Characteristic | Polymer PTC | Ceramic PTC |

|---|---|---|

| Application Scope | Limited to overcurrent & temp. sensing | Overcurrent, temp. sensing & specific apps like degaussing & inrush current limiting |

| Size | Relies on surface area, physically larger | Multilayer design, smaller package size |

| Stability | Lower stability over time | Good long-term stability |

| Cost | Usually more economical | Usually higher cost |

| Performance | Performance proportional to surface area | Stable performance across various applications |

Polymer PTC thermistors are usually lower cost but may be larger and have slightly poorer long-term stability. They are often used for basic circuit protection and temperature detection. For non-demanding simple applications, Polymer PTCs are a good choice.

Selection Advice: Choose Ceramic PTC for high stability and compact spaces; choose Polymer PTC for low cost and less critical tasks.

PTC vs. NTC Thermistors

Core Differences

The main difference between PTC and NTC thermistors lies in how their resistance changes with temperature: PTC resistance increases with temperature rise, while NTC does the opposite – its resistance decreases as temperature rises. This fundamental difference leads to vastly different applications in circuits.

Comparison Table:

| Characteristic | NTC Thermistor | PTC Thermistor |

|---|---|---|

| R-T Relationship | R decreases with T increase | R increases with T increase |

| Main Function | Temperature sensing, inrush current limiting | Current protection, self-regulation |

| Response Time | Fast | Medium to Slow |

| Typical Applications | Power supplies, battery packs, sensors | Fuses, motors, heaters |

| Recovery Characteristic | Passive, requires cooling time | Automatic reset after overload |

NTC performs best when rapid temperature sensing or inrush current limiting is needed; whereas PTC is superior when automatic protection and self-regulation are required.

Application Tip: If you need a device that can reset itself after an overload, the PTC thermistor is your best choice.

Application Scenario Comparison

Different types of thermistors are suitable for different scenarios:

NTCs are commonly found in power supplies, battery packs, and temperature sensors. They react quickly and can effectively manage surge currents.

PTCs are more suitable for safety protection scenarios, including:

Overcurrent protection in safety devices

Motor starting equipment

Temperature control switches

Overtemperature protection

Automatic heating elements in consumer electronics

PTC thermistors increase resistance when heated, helping to limit current and prevent overheating, making them ideal for rechargeable battery and motor protection. They also perform well in self-regulating heaters, maintaining stable temperature and improving energy efficiency.

Technical Note: When protecting equipment from damage due to overheating or electrical faults, PTC thermistors provide a reliable, automatic solution.

PTC Heaters & Industrial Applications

Enclosure Heating Solutions

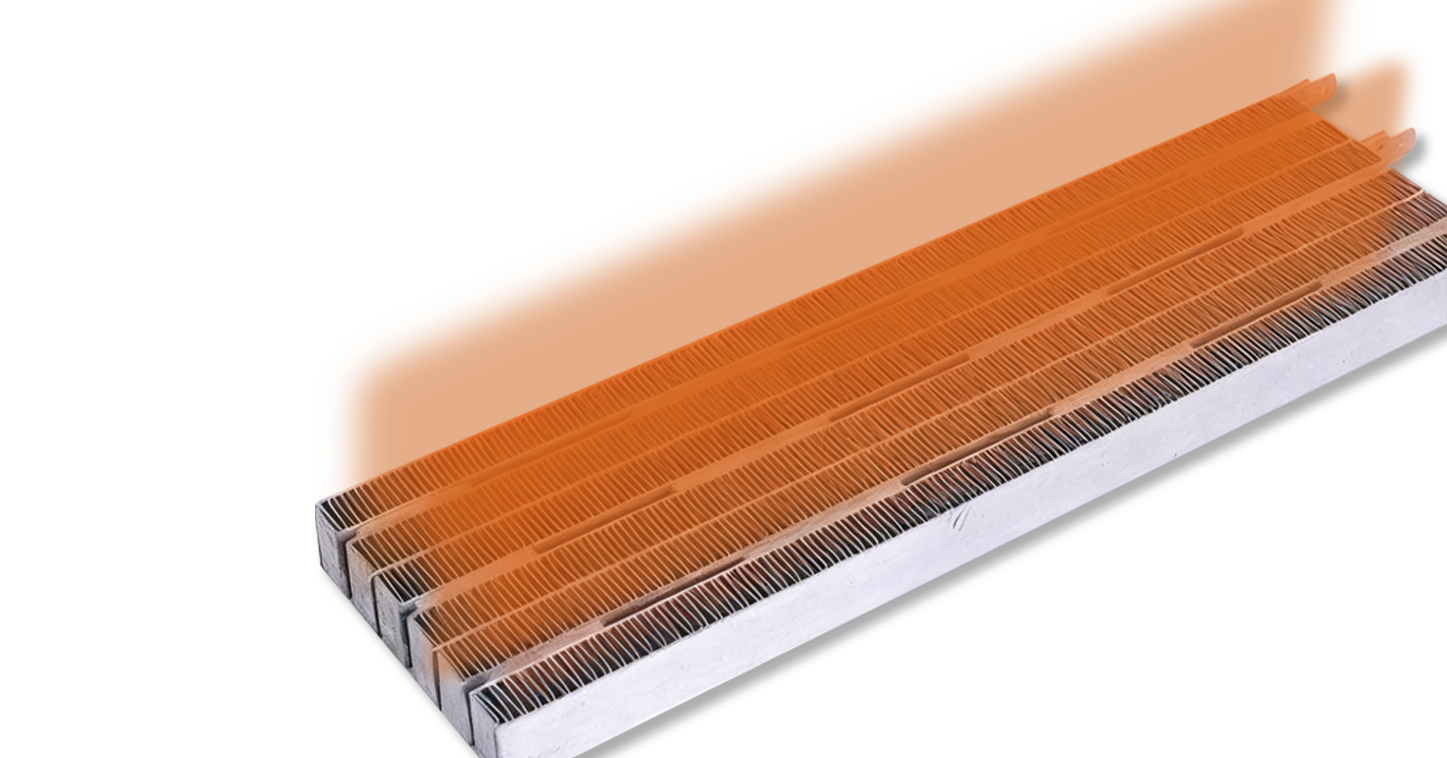

PTC enclosure heaters play an important role in protecting sensitive electronic equipment in control cabinets or telecom racks. These heaters use self-regulating technology to accurately maintain the internal temperature of the enclosure, neither overheating nor wasting energy. PTC heaters activate only when needed, saving electricity while ensuring equipment safety.

Enclosure Heater Features & Benefits:

| Functional Features | User Benefits |

|---|---|

| Self-Regulating PTC Heater | Prevents overheating, maintains stable temperature |

| Activates On-Demand | Saves energy, reduces operating costs |

| Durable Aluminum Housing | Corrosion resistant, long service life |

| IP65 Fully Sealed Design | Protects against dust and water in harsh environments |

These PTC heaters can provide reliable performance in demanding industrial environments.

Thermostat System Integration

Thermostats work in synergy with PTC heaters to provide precise temperature control. You can set the precise internal temperature of a cabinet or enclosure, and the thermostat controls the PTC heater on/off status based on actual conditions. This combination effectively protects electronic equipment from heat damage and cold shock.

These thermostats are easy to install and compatible with most industrial enclosures, helping to avoid condensation, prevent freezing, and extend equipment service life. Pairing a thermostat with a PTC heater provides an intelligent, energy-saving solution for control panels.

Industrial Environment Advantages

The main reasons industries choose PTC heaters:

Energy Efficiency: PTC heaters adjust energy consumption based on ambient temperature, achieving long-term energy savings.

Rapid Response: Heats up quickly, then maintains stability with lower power consumption, achieving fast results and cost reduction.

Easy Maintenance: Simple design, no moving parts, long service life, low maintenance requirements.

Safety & Reliability: Self-regulating function prevents overheating, protects equipment, and reduces fire risk.

Environmental Resistance: Resistant to damage from water, chemicals, and corrosion, suitable for harsh industrial environments.

PTC heaters have a wide range of application scenarios, including industrial ovens, drying equipment, mold heating, and fluid heating systems.

By adopting PTC heater solutions, your sensitive electronic equipment gains comprehensive protection, energy costs are reduced, and equipment service life is extended.

PTC Technical Advantages

Safety and Reliability

PTC thermistors comply with strict safety standards and are designed for demanding working environments. Certification Overview:

| Certification / Standard | Description |

|---|---|

| RoHS | Complies with RoHS regulations |

| IEC 60738-1 | Meets IEC 60738-1 certification requirements |

| IEC 60730-1 | Meets IEC 60730-1 certification requirements |

| AEC-Q200 Rev. D | Complies with AEC-Q200 Rev. D standard |

| UL1434 | UL certification compliant with UL1434 standard |

Beyond certification assurance, PTC thermistors offer genuine reliability – long service life and continuous equipment protection. Unlike traditional fuses, PTC thermistors can reset automatically. For example, a PTC resettable fuse in a lithium-ion battery pack might trip only twice in two weeks and reset within 30 seconds, significantly reducing downtime and operational headaches.

| Function | Description |

|---|---|

| Long Life | Reusable design, lowers maintenance costs |

| High Reliability | Provides consistent overcurrent protection for sensitive components |

| High Efficiency | Self-resetting function reduces repair time, increases work time |

System Suggestion: If you want a system that avoids frequent repairs, choose a PTC thermistor to meet your protection needs.

Energy Efficiency Performance

PTC heating elements help save energy and reduce costs. These heaters can control their own temperature, consuming only the necessary electricity, avoiding energy waste and overheating problems.

PTC heating elements automatically adjust to the suitable temperature, reducing energy consumption.

They consume less electricity than traditional heaters, lowering energy bills.

The self-regulating function ensures they never consume excess power.

PTC thermistors also help reduce maintenance costs by preventing machine overheating and helping cooling systems work more efficiently, extending equipment lifespan and reducing repair expenses.

Industry Observation: As industries seek compact and efficient protection solutions, PTC thermistors stand out. They enhance safety, reduce costs, and help comply with new safety regulations.

Now you understand PTC and its importance in electrical engineering. The following table helps recap the key points:

| Key Point | Description |

|---|---|

| Definition | PTC thermistor resistance increases with temperature rise |

| Principle | Made of ceramic, resistance changes abruptly at critical temperature point |

| Advantages | Stable, compact, fast response, cost-effective, no calibration needed |

PTC technology makes systems safer and more efficient. More and more industries are adopting PTC solutions (like enclosure heaters and thermostats) to protect equipment and improve reliability.

Automation and energy efficiency needs drive application popularity.

Companies invest in smarter designs and better collaboration.

If reliable performance is required, consider using suitable PTC solutions in your next project.

Frequently Asked Questions

What does PTC stand for in Electrical Engineering?

PTC stands for Positive Temperature Coefficient, describing a thermistor whose resistance increases with rising temperature. These devices help protect circuits and ensure equipment safety.

How do PTC Thermistors protect electronic devices?

PTC thermistors act like intelligent fuses. When the temperature gets too high, they increase resistance and limit current, preventing overheating and ensuring smooth equipment operation.

Where are PTC Heaters applicable?

PTC heaters are suitable for control cabinets, telecom racks, and industrial enclosures. They are ideal for keeping electronic equipment dry, preventing condensation, and maintaining a stable temperature.

What is the Curie Temperature of a PTC Thermistor?

The Curie Temperature is the critical point at which the thermistor's resistance rises sharply, providing automatic protection – the device almost blocks current when overheated.

Do PTC Heaters need to be used with a Thermostat?

Yes, using a thermostat with a PTC heater enables precise temperature control. Set the desired temperature, and the system will keep the equipment safe and energy-efficient.

Copyright ©️ LINKWELL ELECTRIC (Shanghai) Co., Ltd. 沪ICP备12048522号-2

cooling fan

Axial Fan

top exhaust fan

Centrifugal fan

DC fan

Industrial air conditioner

transformer

Terminals

thermostat

heater

Distribution Cabinet

waterproof box

Electric control cabinet accessories