Views: 0 Author: Site Editor Publish Time: 2026-01-30 Origin: Site

In modern industrial production lines, automation control systems, or the power distribution rooms of intelligent buildings, neatly arranged control cabinets serve as the central nervous system for various equipment. When you open a cabinet door, beyond the orderly wiring and modules, there is always a seemingly simple yet crucial device standing silently inside—the control transformer. It may not be as intelligent as a PLC or as eye-catching as a frequency converter, but it is the "invisible guardian" and "power source" that ensures the safety, stability, and efficient operation of the entire control system.

Have you ever wondered what kind of intricate structure and ingenuity lies beneath its sturdy exterior? How does it convert high-voltage power into the stable low voltage required by instruments, relays, and controllers? Today, let's delve into the interior of a Linkwell control transformer together, unveiling how each of its key components works in harmony to provide rock-solid power protection for your industrial applications.

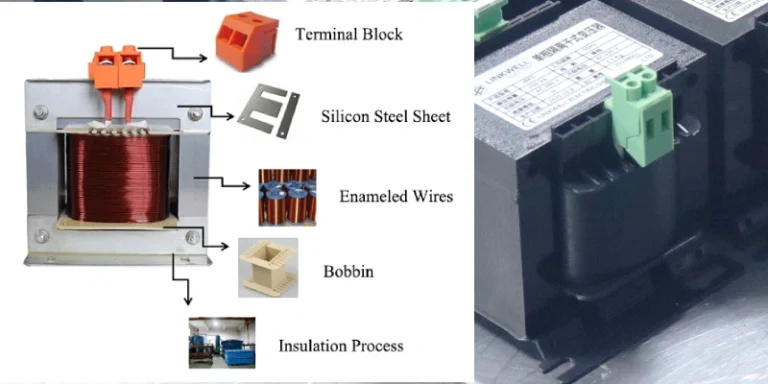

Part 1: What's Inside a Transformer? An Overview of Core Components

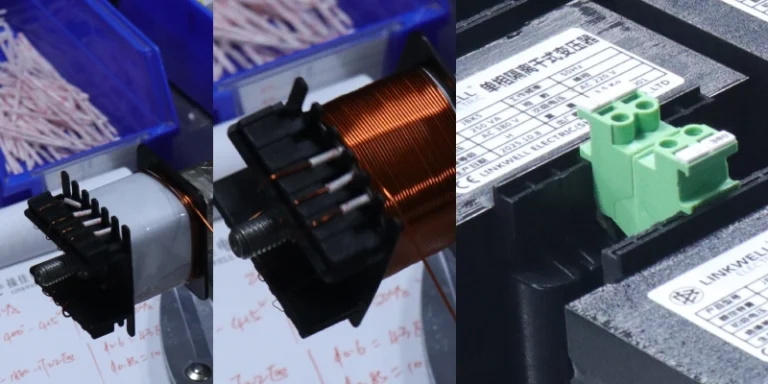

Opening the enclosure of a control transformer reveals not just simple coils and iron blocks, but a system of precision design and strict manufacturing. Here are all the internal parts that constitute its core functionality:

Robust Magnetic Core (Core): The transformer's "backbone" and "magnetic pathway highway," typically laminated from high-performance silicon steel sheets or amorphous alloy. It is responsible for efficiently guiding magnetic flux to achieve energy coupling and transfer.

Copper Windings (Windings): Comprising the primary winding and secondary winding. They are the transformer's "arteries" and "veins." The primary receives input electrical energy, and the secondary outputs the required voltage, completing the step-up or step-down voltage transformation through the principle of electromagnetic induction.

Insulation System (Insulation): Includes insulation paper, resin, spacers, etc. It is the "isolation barrier" that ensures safety, guaranteeing complete electrical isolation between windings, between windings and the core, and between all live parts and the enclosure, preventing short circuits and leakage.

Terminals and Leads (Terminals): Clearly marked input (primary) and output (secondary) connection points. They are the "secure gateways" for electrical energy entering and exiting the transformer, ensuring firm and reliable connections.

Mounting Frame and Protective Enclosure (Frame & Enclosure): The "armor" that provides mechanical support, physical protection (against dust, moisture, electric shock), and heat dissipation channels for all internal components.

In industrial control cabinets and panels, the commonly used Linkwell control transformers typically feature a compact design, adapting to standard installation dimensions (e.g., 380mm x 600mm x 600mm or 320mm x 300mm x 240mm), making perfect use of the cabinet's internal space.

Part 2: Core Decryption: The Function and Synergy of Each Component

1. Magnetic Core: The Foundation of Efficiency and Performance

The magnetic core is the soul of a transformer's performance. Linkwell selects high-quality silicon steel or amorphous alloy, using special lamination processes to minimize "eddy current losses" and "hysteresis losses." This means less electrical energy is wasted as heat, resulting in higher operational efficiency and lower long-term operating costs. Its design and materials directly determine the transformer's voltage handling capability, temperature rise, and overall reliability.

Impact of Material Selection on Performance:

| Material | Main Characteristics | Contribution to Transformer Performance |

Silicon Steel | High magnetic permeability, cost-effective | Reduces eddy currents through lamination, improves efficiency, widely used in general industrial scenarios. |

Amorphous Alloy | Extremely low core loss characteristics | Significantly reduces no-load losses (up to 70% less than silicon steel), outstanding energy-saving effect, suitable for long-term operating equipment. |

Ferrite | Good high-frequency characteristics, high resistivity | Suitable for electronic transformers like high-frequency switching power supplies, reduces high-frequency losses. |

2. Windings: The Precise Voltage Converter

Windings are the executors of voltage transformation. The primary winding connects to the system power supply (e.g., 480V AC), while the secondary winding outputs the safe voltage required by the control circuit (e.g., 120V AC or 24V AC). Linkwell uses high-purity copper wire coated with high-temperature resistant enamel of different classes (e.g., PEW, UEW), ensuring excellent conductive performance and reliable insulation. The turns ratio of the windings is precisely calculated to guarantee the accuracy and stability of the output voltage, providing clean power for sensitive PLCs, sensors, and contactor coils.

3. Insulation System: The Guarantee of Safety and Longevity

In the compact, potentially high-temperature and high-humidity environment inside a cabinet, the reliability of the insulation system is paramount. Linkwell's insulation materials (such as DMD prepreg, Nomex paper) possess high dielectric strength, flame retardancy (V0 rating), and heat resistance (Class B, F, H ratings). It not only prevents internal short circuits but also effectively resists moisture, dust, and chemical corrosion, ensuring the transformer has an extended service life in harsh industrial environments and fully complies with international safety standards like UL, CE, and IEC.

4. Cooling and Protection: The Guardian of Stable Operation

The heat generated during transformer operation must be effectively managed. Linkwell control transformers primarily employ Natural Air Cooling (AN) or Forced Air Cooling (AF) designs. The compact structure and reasonable air duct design facilitate air convection for heat dissipation. Some models also incorporate built-in temperature protection devices (e.g., thermal relays), which can automatically cut off the circuit in case of overheating, providing dual protection. The sturdy enclosure offers IP20 or higher protection ratings, preventing ingress of foreign objects and accidental contact, ensuring safe operation under any working condition.

Part 3: Why Choose Linkwell Control Transformers?

Facing numerous choices in the market, Linkwell has become the trusted choice for numerous system integrators and end-users worldwide, thanks to the following core advantages:

Outstanding Reliability: From raw materials to finished products, a strict quality control system (ISO 9001 certified) ensures every transformer possesses high reliability, ready for use upon delivery.

Powerful Customization Capability: We understand that standard products cannot meet all needs. Linkwell offers flexible customization services, including:

Diverse Voltage Combinations: Support for customizing various input/output voltages.

Wide Power Range Selection: Power coverage from 60VA to 100kVA.

Special Installation Methods: Adaptable to DIN rail, panel mount, or base mounting.

Special Protection Requirements: Can provide special coatings, sealing, or terminal types.

Excellent Electrical Performance: High surge withstand capability, easily handling instantaneous current surges during motor or solenoid valve startup, maintaining stable output voltage.

Global Compliance and Safety Certifications: Products comply with various international certifications such as UL, cUL, CE, RoHS, assisting your equipment in smoothly entering global markets.

Professional Service and Support: We have an experienced technical team providing full-process service from selection consultation to after-sales support.

Conclusion

A high-quality control transformer is the cornerstone of a safe, stable, and efficient industrial control system. Every component inside it—from the efficient magnetic core and precise windings to the reliable insulation and sturdy enclosure—carries a mission of vital importance.

Choosing Linkwell means choosing not just a component, but a trustworthy power solution partner. We are committed to integrating卓越的 engineering technology, stringent quality standards, and customer-centric service philosophy into every transformer, safeguarding your equipment and business.

Frequently Asked Questions (FAQ)

Q1: What is the difference between a control transformer and a regular power (distribution) transformer?

A: They have different design objectives. Control transformers are primarily used to provide stable, isolated low-voltage power (typically <600V) for control circuits, instruments, relays, etc., focusing on precision, safety, and compact size. Power transformers are mainly used for power transmission and distribution in grids, handling high-voltage (typically >1kV) energy transfer and step-down, focusing on efficiency and massive power capacity. The two are not interchangeable.

Q2: How do I select the right control transformer for my control cabinet?

A: Mainly based on the following three points:

Voltage Match: Confirm the input (primary) voltage and the required output (secondary) voltage.

Sufficient Power (VA Rating): Calculate or estimate the total power consumption of all loads that need to be powered by this transformer (e.g., contactor coils, PLC power modules, indicator lights) and leave approximately 20% margin.

Physical Size and Installation Method: Measure the available space inside the cabinet and select a model with suitable dimensions (e.g., 380x600x600mm) and installation method (base or rail mount).

Q3: What does the insulation class (e.g., Class B, F, H) represent?

A: The insulation class indicates the maximum temperature that the transformer winding insulation material can withstand continuously. For example, Class F means it can withstand 155°C. A higher insulation class means the transformer has a longer expected lifespan under the same load or better tolerance during overload conditions.

Q4: Can Linkwell provide non-standard transformers with special specifications?

A: Absolutely. Customization is one of our core strengths. Whether it's a special voltage ratio, higher protection rating, specific certification requirements, or unique mechanical structure, our engineering team can collaborate with you to provide the perfect solution.

Copyright ©️ LINKWELL ELECTRIC (Shanghai) Co., Ltd. 沪ICP备12048522号-2

cooling fan

Axial Fan

top exhaust fan

Centrifugal fan

DC fan

Industrial air conditioner

transformer

Terminals

thermostat

heater

Distribution Cabinet

waterproof box

Electric control cabinet accessories