Views: 10 Author: Site Editor Publish Time: 2022-05-09 Origin: Site

In industrial power distribution operation, transformer is an indispensable product, - static electrical equipment products,

The most common is dry-type transformers. Dry-type transformers are used in electrical equipment, high-tech industries, local lighting, airports, high-rise buildings, mechanical equipment and other places. They are widely used. Before users choose a transformer, familiarize themselves with it. It is necessary to master the basic knowledge of transformers, which can help to avoid many detours when selecting products.

Material description for dry-type transformers

A Iron core

New high-quality high-silicon silicon steel sheets are used, and the main materials are high-quality silicon steel sheets of 0.35 thickness H18, H14, H12, and Z11. We choose suitable materials according to the requirements and usage conditions of the guest rooms, so as to achieve the best performance design of the dry-type transformer. (The conventional material is a new high-quality silicon steel sheet).

B wire

Using PEW, UEW, EIW, SEIW, FEAI enameled wire and glass wire covered wire, the temperature resistance grades are F grade (155℃), H grade (180℃), HC grade (200℃), C grade (220℃). (The conventional temperature resistance grade is H grade 180 ℃).

C insulating material

Using high temperature resistant insulating paper as insulating material, it has multiple properties of high temperature insulation, flame retardant and moisture resistance.

D Terminal block

The terminal block is used for low power, which is beautiful in appearance and has excellent pressure resistance, temperature resistance and flame retardant performance. High-power uses high-quality copper bars.

E iron feet

The CNC bending cold-rolled plate is mainly used, and there are environmental protection electroplating options such as multi-colored (golden), blue zinc (silver white), white zinc (ivory white), and surface anodized (black).

The use environment of dry-type transformers

1 Applicable altitude: ≤5000m

2 Ambient temperature: -15℃~+45℃

3 Relative humidity: ≤90%

Let me give a brief overview of Linkwell.

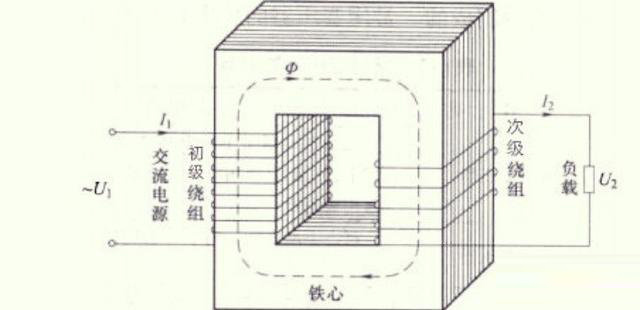

What is a transformer

In the AC circuit, the device that increases or decreases the voltage is called a transformer. The transformer can convert any value of voltage into the voltage value we need with the same frequency to meet the transmission, distribution and use requirements of electric energy. For example, the electricity from a power plant has a low voltage level, and the voltage must be increased to be transported to a distant power consumption area. The power consumption area must be reduced to a suitable voltage level to supply power equipment and daily electricity. Equipment.

Let's talk about the most used transformers - dry-type transformers

Simply speaking, dry-type transformers refer to transformers whose iron cores and windings are not immersed in insulating oil.

Dry-type transformers are the main components of various power supplies and electrical equipment. Isolated dry-type transformers are composed of cylindrical windings and laminated iron cores. The iron cores are made of new high-quality high-silicon silicon steel sheets stacked with full oblique joints. The company adopts advanced production technology, including imported Spanish winding machines and a full set of vacuum pressure dipping equipment; the winding adopts the method of unwrapped and whole-column winding; the dry-type transformer is vacuum dipped to make the insulation level of the dry-type transformer reach F level or Class H. The output and input voltage of dry-type transformers can be designed according to customer requirements. There are single-phase, three-phase or multiple input and output and other specifications.

A dry-type transformer is a device used to convert a certain value of AC voltage (current) into another or several different values of voltage (current) with the same frequency.

Material description for dry-type transformers

A Iron core

New high-quality high-silicon silicon steel sheets are used, and the main materials are high-quality silicon steel sheets of 0.35 thickness H18, H14, H12, and Z11. We choose suitable materials according to the requirements and usage conditions of the guest rooms, so as to achieve the best performance design of the dry-type transformer. (The conventional material is a new high-quality silicon steel sheet).

B wire

Using PEW, UEW, EIW, SEIW, FEAI enameled wire and glass wire covered wire, the temperature resistance grades are F grade (155℃), H grade (180℃), HC grade (200℃), C grade (220℃). (The conventional temperature resistance grade is H grade 180 ℃).

C insulating material

Using high temperature resistant insulating paper as insulating material, it has multiple properties of high temperature insulation, flame retardant and moisture resistance.

D Terminal block

The terminal block is used for low power, which is beautiful in appearance and has excellent pressure resistance, temperature resistance and flame retardant performance. High-power uses high-quality copper bars.

E iron feet

The CNC bending cold-rolled plate is mainly used, and there are environmental protection electroplating options such as multi-colored (golden), blue zinc (silver white), white zinc (ivory white), and surface anodized (black).

The use environment of dry-type transformers

1 Applicable altitude: ≤5000m

2 Ambient temperature: -15℃~+45℃

3 Relative humidity: ≤90%

Features of dry-type transformers

1. Adopt domestic advanced technology, high mechanical strength, strong short-circuit resistance, small partial discharge, good thermal stability, high reliability and long service life;

2. Safe, fireproof, pollution-free, and can be directly operated in the load center;

3. Good heat dissipation performance, strong overload capacity, can increase capacity operation when forced air cooling;

4. Low loss, low noise, obvious energy saving effect, maintenance free;

5. Good moisture resistance, suitable for operation in high humidity and other harsh environments;

6. Small size, light weight, small footprint and low installation cost.

The above are basic common misunderstandings about some transformers. Do you understand?

Welcome to learn about all aspects of transformer products! Tel: 400-671-6715 155 9909 4305

Copyright ©️ LINKWELL ELECTRIC (Shanghai) Co., Ltd. 沪ICP备12048522号-2

cooling fan

Axial Fan

top exhaust fan

Centrifugal fan

DC fan

Industrial air conditioner

transformer

Terminals

thermostat

heater

Distribution Cabinet

waterproof box

Electric control cabinet accessories